Florida Memory is administered by the Florida Department of State, Division of Library and Information Services, Bureau of Archives and Records Management. The digitized records on Florida Memory come from the collections of the State Archives of Florida and the special collections of the State Library of Florida.

State Archives of Florida

- ArchivesFlorida.com

- State Archives Online Catalog

- ArchivesFlorida.com

- ArchivesFlorida.com

State Library of Florida

Related Sites

Description of previous item

Description of next item

State Road Department Bulletin: Mixed-in-Place Sand Asphalt in Florida, 1932

Source

Description

Date

Creator

Contributors

Format

Coverage

Topic

Geographic Term

Due to the great and many requests received from various Engineers, County Officials and Contractors concerning the "Mixed-in-place" Sand Asphalt type of road surfacing which the State Road Department of Florida has been building for the past two years, this bulletin is issues. An attempt is here made to outline in concise form the various steps in construction and the mechanical procedure involved in building this type of asphalt surface. The bulletin is presented, not as a technical treatise, but as a reference paper of fact and of work accomplished by the Department.

The "Mixed-in-place Sand Asphalt" is an asphaltic mixture, composed of the existing road material, mixed thoroughly with asphaltic oil, in which all mixing is done mechanically on the road.

There are a few requisites which are essential for the success of this type construction; namely, dry warm climate, medium or light traffic, sandy soils and last but not least, good drainage.

It may be well remembered that the "Mixed-in-place Sand Asphalt" road is not the ultimate solution of road surfaces regardless of location, available material, or volume of traffic. The contention is made, however, that this type road surface does have merit and utility in some sections of Florida where the existing road material is suitable, climate hot and dry and traffic not above medium density. It is not recommended for use where extremely wet climates are predominant, the existing material is not sand, traffic heavy, or drainage conditions poor.

The question is quite often raised. What volume of traffic will this type surface carry? Frankly, we do not know, as out only work has been in sparsely populated sections where traffic is light and then only subjected to traffic less than two years. It is estimated that a road of this type will safely carry from 1000 to 1500 vehicles per day.

The "Mixed-in-place Sand Asphalt" road, so far, has been a marked success in Florida, and has passed its experimental stage. From the results now being obtained it gives promise to many more miles of similar construction, in locations where conditions are suitable, a road surface badly needed, and limited funds are available for construction.

2

Title

Subject

Description

Creator

Source

Date

Contributor

Format

Language

Type

Identifier

Coverage

Geographic Term

Thumbnail

ImageID

topic

Subject - Corporate

Subject - Person

Transcript

BULLETIN

Mixed-in-Place Sand Asphalt In Florida

BULLETIN

Mixed-in-Place Sand Asphalt

BY H.C. WEATHERS

DIVISION ENGINEER OF TESTS

GAINESVILLE, FLORIDA

JANUARY 1, 1932

Due to the great and many requests received from various Engineers, County Officials and Contractors concerning the "Mixed-in-place" Sand Asphalt type of road surfacing which the State Road Department of Florida has been building for the past two years, this bulletin is issues. An attempt is here made to outline in concise form the various steps in construction and the mechanical procedure involved in building this type of asphalt surface. The bulletin is presented, not as a technical treatise, but as a reference paper of fact and of work accomplished by the Department.

The "Mixed-in-place Sand Asphalt" is an asphaltic mixture, composed of the existing road material, mixed thoroughly with asphaltic oil, in which all mixing is done mechanically on the road.

There are a few requisites which are essential for the success of this type construction; namely, dry warm climate, medium or light traffic, sandy soils and last but not least, good drainage.

It may be well remembered that the "Mixed-in-place Sand Asphalt" road is not the ultimate solution of road surfaces regardless of location, available material, or volume of traffic. The contention is made, however, that this type road surface does have merit and utility in some sections of Florida where the existing road material is suitable, climate hot and dry and traffic not above medium density. It is not recommended for use where extremely wet climates are predominant, the existing material is not sand, traffic heavy, or drainage conditions poor.

The question is quite often raised. What volume of traffic will this type surface carry? Frankly, we do not know, as out only work has been in sparsely populated sections where traffic is light and then only subjected to traffic less than two years. It is estimated that a road of this type will safely carry from 1000 to 1500 vehicles per day.

The "Mixed-in-place Sand Asphalt" road, so far, has been a marked success in Florida, and has passed its experimental stage. From the results now being obtained it gives promise to many more miles of similar construction, in locations where conditions are suitable, a road surface badly needed, and limited funds are available for construction.

2

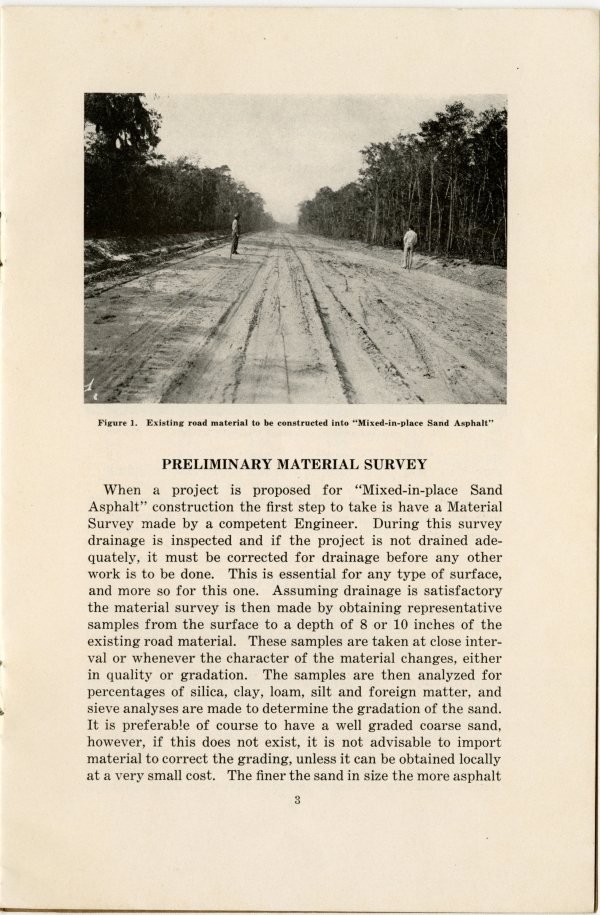

PRELIMINARY MATERIAL SURVEY

When a project is proposed for "Mixed-in-place Sand Asphalt" construction the first step to take is have a Material Survey made by a competent Engineer. During this survey drainage is inspected and if the project is not drained adequately, it must be corrected for drainage before any other work is to be done. This is essential for any type of surface, and more so for this one. Assuming drainage is satisfactory the material survey is then made by obtaining representative samples from the surface to a depth of 8 or 10 inches of the existing road material. These samples are taken at close interval or whenever the character of the material changes, either in quality of gradation. The samples are then analyzed for percentages of silica, clay, loam, silt and foreign matter, and sieve analyses are made to determine the gradation of the sand. It is preferable of course to have a well graded coarse sand, however, if this does not exist, it is not advisable to import material to correct the grading, unless it can be obtained locally at a very small cost. The finer the sand in size the more asphalt

3

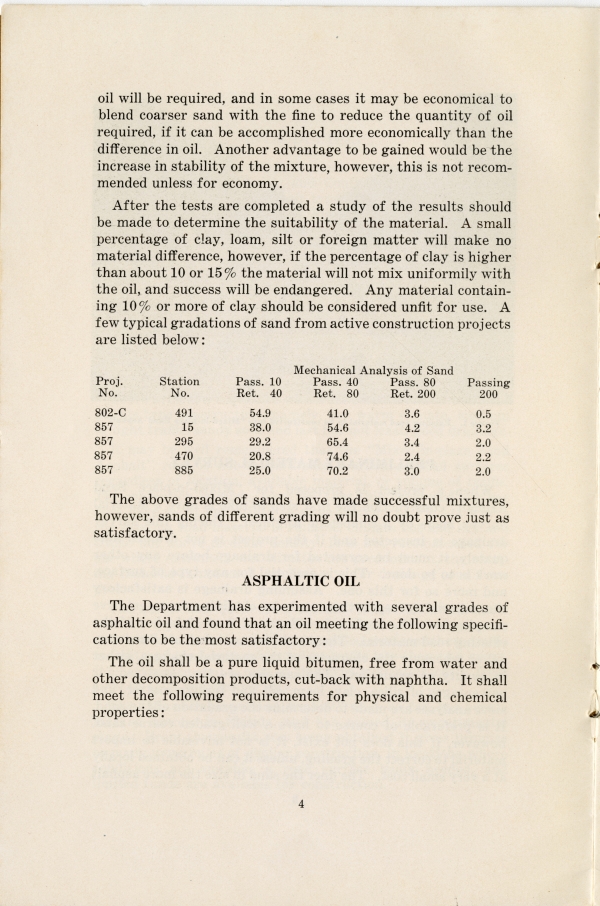

After the tests are completed a study of the results should be made to determine the suitability of the material. A small percentage of clay, loam, silt or foreign matter will make no material difference, however, if the percentage of clay is higher than about 10 or 15% the material will not mix uniformly with the oil, and success will be endangered. Any material containing 10% or more of clay should be considered unfit for use. A few typical gradations of sand from active construction projects are listed below:

[table of gradations of sand from construction projects]

The above grades of sand have made successful mixtures, however, sands of different grading will no doubt prove just as satisfactory.

ASPHALTIC OIL

The Department has experimented with several grades of asphaltic oil and found that an oil meeting the following specifications to be the most satisfactory:

The oil shall be a pure liquid bitumen, free from water and other decomposition products, cut-back with naphtha. It shall meet the following requirements for physical and chemical properties:

4

[table of asphaltic oil specifications]

The penetration of the base asphalt, before cutting back with naphtha shall be between 85 and 100 penetration.

The Department reserves the right to change the above if conditions should warrant. Same would consist in a change of asphaltic content and percent of naphtha.

The Department has found the above oil to be more satisfactory in most cases than any of the others experimented with, although on one project, where the existing road material contained a high percentage of silt, loam and some clay, mixing was affected by a tendency of the material to ball with the oil. To eliminate this, or to obtain better results it was found neces-

5

DETERMINING AMOUNT OF OIL REQUIRED

The amount of oil needed to make a good job varies with the nature and grading of the material to be mixed with the oil. In this respect, this type of mix follows the theory of all asphalt mixtures, in which the quantity of oil shall be sufficient to entirely coat each individual particle of the mineral aggregate and a slight excess to fill voids and produce durability. Finer graded material contains more individual particles per unit volume, therefore, there is more surface area to be coated and more oil is required.

The surface character of the material also influences the amount of oil necessary, as a rough, rugged surface will require much more oil than a smooth one. In view of this fact and also the great changes in gradation of the road material in different locations, and even on the same project, it has been impossible to date to create a cut and dried table of oil quantities necessary for this type of construction.

The method used at the present time to determine the amount of oil necessary to produce a satisfactory mixture is a combination laboratory investigation and trial mix in the field. Samples of the material are analyzed for quality and gradation in the laboratory and small batches made up. From the results of this study the Field Engineer is furnished with an approximate quantity of oil necessary for good results. He is then to use his own judgement after trying a section using the predetermined quantity of oil, and from visual inspection of the actual road mix vary the quantity of oil, if necessary, to accomplish satisfactory results. The final mixture, after the last application of oil has been added and the mixture thoroughly mixed, should have a black, glossy appearance. Any mix having a brownish color is too lean and should be reworked by adding more oil and mixing continued until the black appearance is produced.

On the work completed in this State to date the oil quantity has averaged about five (5) gallons per square yard of pavement

6

six (6) inches compacted thickness. Some sections have required as much as three (3) gallons and others as much as 6.5 on account of the grading and quality of the material.

Following is a table showing some of the typical sand grading used on active projects and the quantity of oil necessary to produce satisfactory results:

[table of oil quantities]

7

SEQUENCE OF MIXING OPERATIONS

Beginning Operations

After the proposed project has been investigated and found satisfactory for "Mixed-in-place Sand Asphalt" construction it is advised that a four (4) mile section be selected to begin operations, and completed before another section is started. This has been found by experience to give best results for if an entire project of several miles, or a section greater than four (4) miles is undertaken, trouble will be experienced in mixing

[caption] Figure 4. Tractor-drawn grader-12-foot glade useful in windrowing material, assisting mixing, and shaping surface. Note extra wide tires, essential for this class of work.

8

and a waste of oil will probably occur due to rapid volatilization of the cut-back oil before mixing is complete.

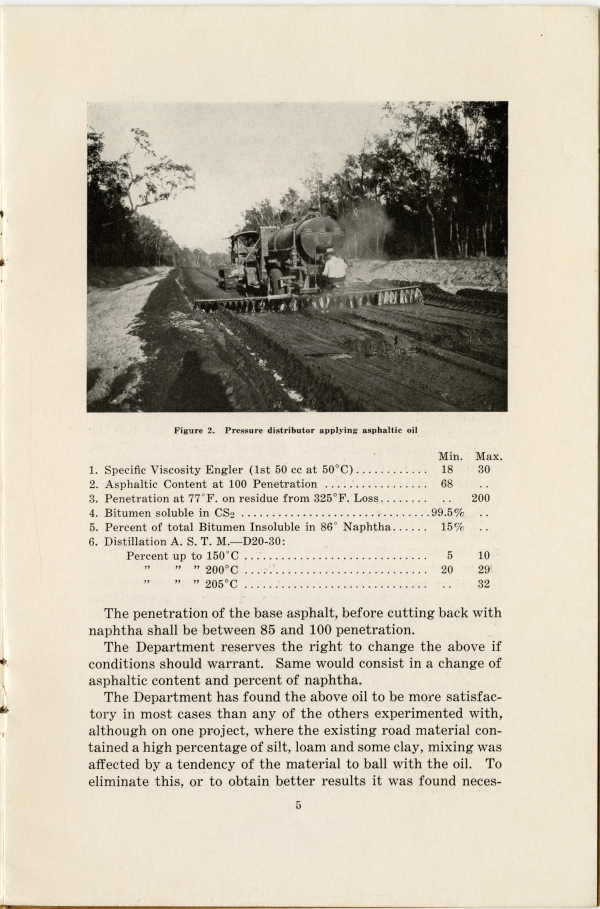

As practically all projects adaptable to this type construction are sandy as illustrated in Figure 1, hauling asphalt material in the pressure distributor is very difficult. It is necessary to boost the power of the distributor with a tractor, for the first application of asphalt. For this reason it is suggested that a starting point be made midway the four (4) mile section previously selected. Starting at the center of the four (4) mile section, a sub-section of 2500 feet is treated with approximately two (2) gallons of asphaltic oil per square yard applied in one (1) application as illustrated in Figure 2. This will aid in hauling material through the section without getting stuck with the distributor under its own power. Before any mixing of this section is attempted operations are moved to the extreme end of the two (2) mile section and this is worked back toward the center starting point, in small sections of 1/3 the two (2) mile section (approximately 3300 feet) and completed before starting on the next 1/3 section. This operation is continued until

9

the center starting point is reached, then the other half of the original four (4) mile section is worked in the same manner.

Operation of 3 Furrow Gang Plow

After the before mentioned two (2) gallons of asphaltic oil per square yard has been applied, the road for its entire width and length of the 3300-foot section being constructed, is plowed thoroughly with a three (3) furrow gang plow as illustrated in Figure 3. The material is uniformly loosened up for a depth of seven or eight inches.

Windrowing

When the material has been uniformly plowed to the proper depth, the tractor drawn road grader with a 12' blade as illustrated in Figure 4 is used to push the material from the center to the shoulders, to a depth of approximately 3 inches, and store the pushed out material in two windrows on each side of the road, completely clearing the 20 ft. width, or the plan width the pavement is to occupy. The full 20 ft. width is then treated with about three (3) 0.4 gallon per square yard applications of asphaltic oil.

10

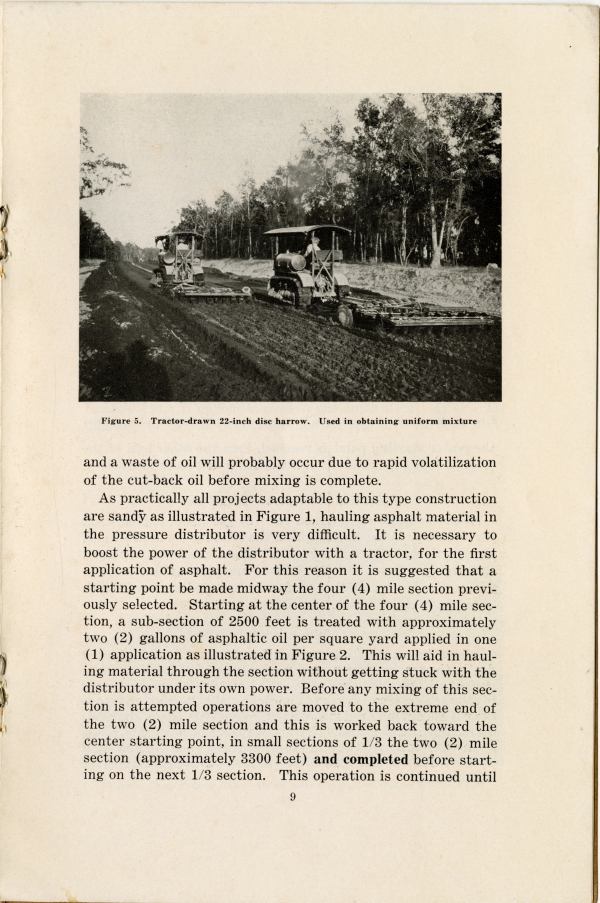

Figure 5 shows the tractor-drawn 22" disc harrow mixing the oil and sand. This piece of equipment is used immediately after each 0.4 gallon application of oil. Quite often for bet results two or three harrow units are used in tandem, and these run continuously so that each application of oil is cut into the road material before the next application is made. After sufficient numbers of applications of oil have been made, and a uniform, black mix has been obtained for a depth of about four (4) inches, the windrower material, which was previously worked out onto the shoulders, is pulled back into place with the grader and distributed uniformly over the 20 ft. width of mixed material. While this is being pulled back into place, a 0.4 gallon per square yard application of oil is made and the mixing continues with the disc harrows, and grader. Additional 0.4 gallon applications are then made and mixing continued until about 1.2 to 1.5 gallons of asphaltic oil has been applied or more applications if necessary. These figures of 1.2 to 1.5 gallons in exclusive of the first two (2) gallons applied at one application. After this quantity of oil has been used, and mixing with harrows and

[caption] Figure 7. Tractor-drawn grader--12-foot blade making final shaping prior to rolling

11

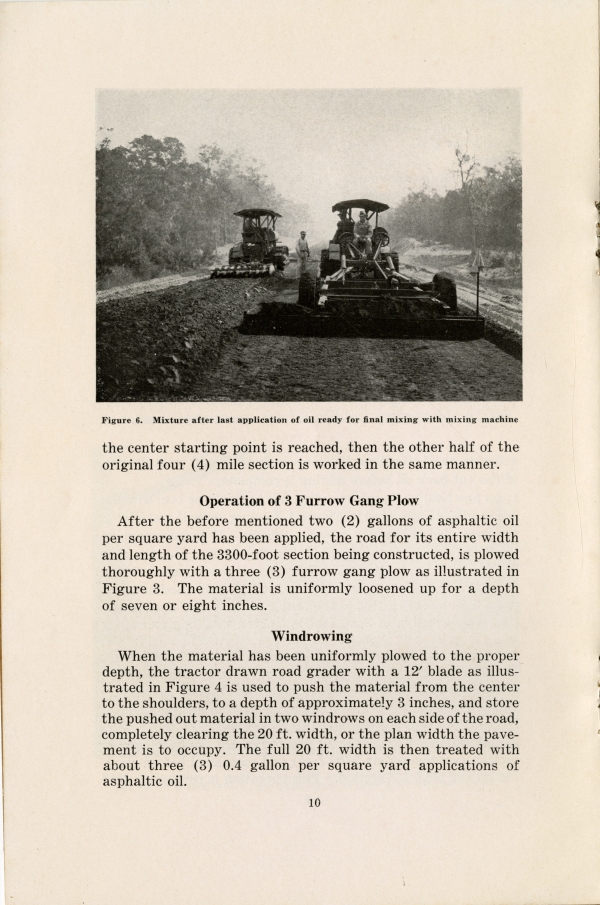

grader continued sufficiently, the mix will have a uniform black appearance, as illustrated in Figure 6.

The final mix is obtained by mixing with harrows and rolling the material back and forth from center to edges and back again several times with the grader. At the same time the edges should be plowed with the 3 furrow gang plow shown in Figure 3 to obtain uniform depth of mixture on edges and quarters. If this is not done there will be uneven thickness of mix at these places, as it is very difficult to obtain a uniform depth on the edges, without the use of the plow. After this is accomplished, the harrows are taken off and the mixture is lightly windrowed with the graders.

Operating of Mixing Machine

When graded out smooth and to the proper contour the mixing machine as shown in right of Figure 6 is used. This machine has diagonal steel blades running in opposite directions. It is run over the mixture two or three times until the mixture is uniformly mixed and has a black appearance to a depth of 2 or 3 inches on top. The completed pavement, while one course,

12

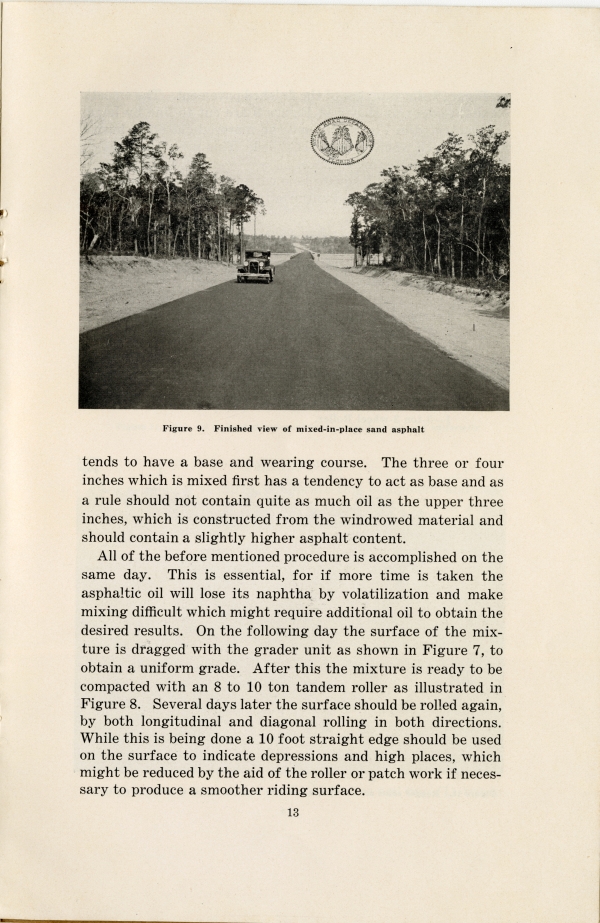

tends to have a base and wearing course. The three or four inches which is mixed first has a tendency to act as base and as a rule should not contain quite as much oil as the upper three inches, which is constructed from the windrowed material and should contain a slightly higher asphalt content.

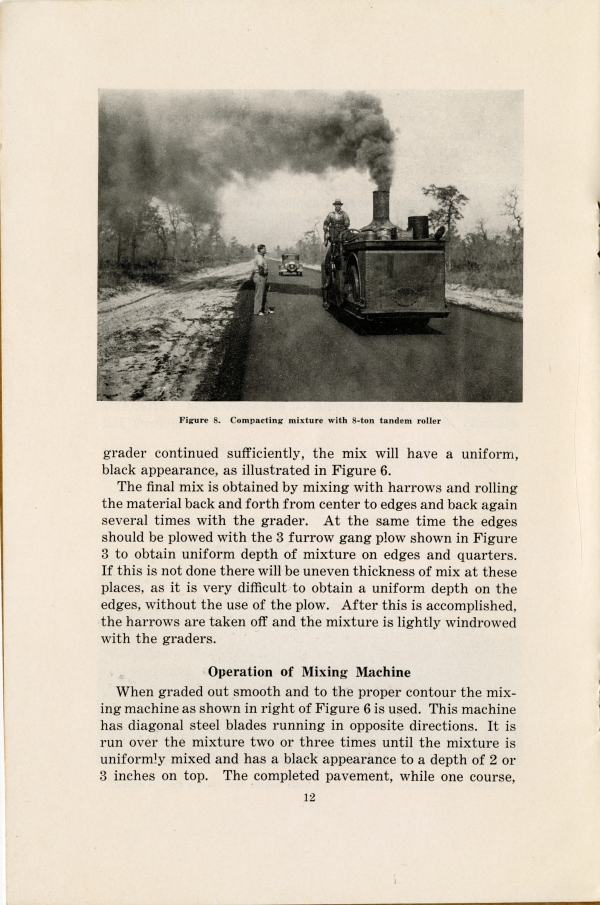

All of the before mentioned procedure is accomplished on the same day. This is essential, for it more time is taken the asphaltic oil will lose its naphtha by volatilization and make mixing difficult which might require additional oil to obtain the desired results. On the following day the surface of the mixture is dragged with the grader unit as shown in Figure 7, to obtain a uniform grade. After this the mixture is ready to be compacted with an 8 to 10 ton tandem roller as illustrated in Figure 8. Several days later the surface should be rolled again, by both longitudinal and diagonal rolling in both directions. While this is being done a 10 foot straight edge should be used on the surface to indicate depressions and high places, which might be reduced by the aid of the roller or patch work if necessary to produce a smoother riding surface.

13

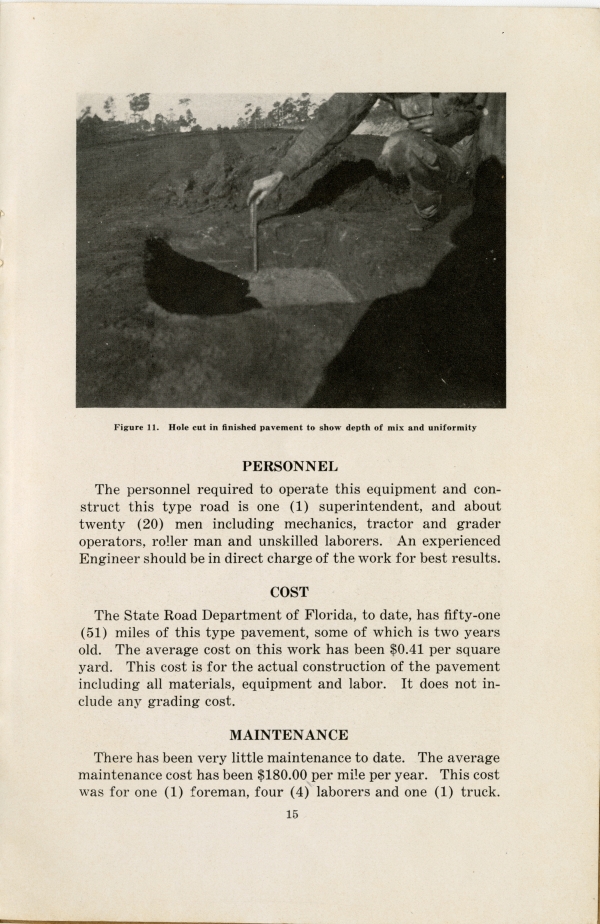

Figure 11 shows a square black hole cut in the finished pavement to indicate the depth and uniformity of the pavement.

EQUIPMENT REQUIRED

A complete complement of equipment for a mixed-in-place sand asphalt project consists of the following:

3-Offset tractor disc harrows-22" disc-7 1/2' cut.

1-3 Furrow gang plow-14" bottom.

1-12' Grader.

2-Distributors.

5-Tractors (Two (2) 10-ton and three (3) 5-ton).

1-Mixing machine with 12' blade.

1-8 or 10-ton Tandem Roller

1-3-ton 3-wheel Roller.

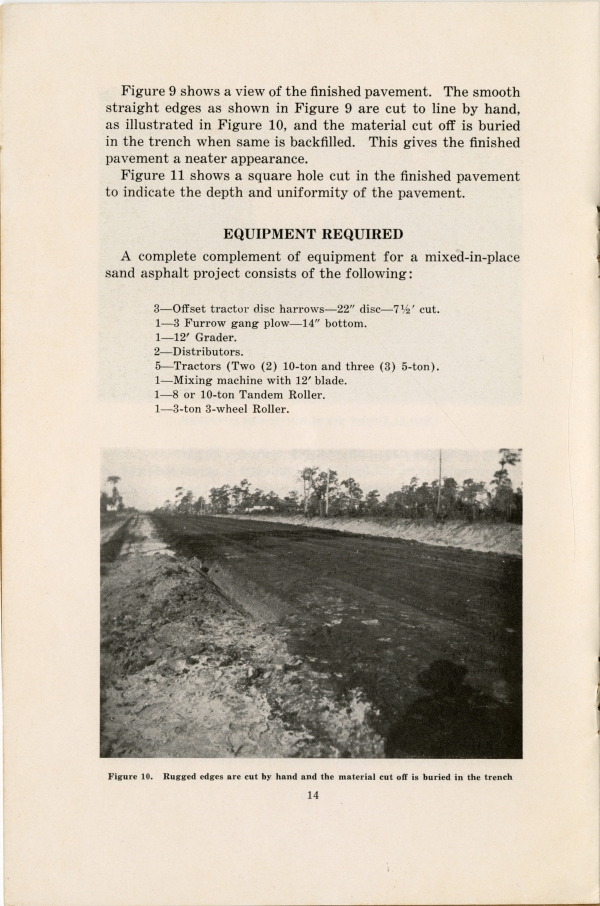

[caption] Figure 10. Rugged edges are cut by hand and the material cut off is buried in the trench

14

PERSONNEL

The personnel required to operate this equipment and construct this type road is one (1) superintendent, and about twenty (20) men including mechanics, tractor and grader operators, roller man and unskilled laborers. An experienced Engineer should be in direct charge of the work for best results.

COST

The State Road Department of Florida, to date, has fifty-one (51) miles of this type of pavement, some of which is two years old. The average cost on this work has been $0.41 per square yard. This cost is for the actual construction of the pavement including all materials, equipment and labor. It does not include any of the grading cost.

MAINTENANCE

There has been very little maintenance to date. The average maintenance cost has been $180.00 per mile per year. This cost was for one (1) foreman, four (4) laborers and one (1) truck.

15

This type of road has been a life saver in the section of Florida in which it is being constructed. The location borders the Gulf of Mexico and traverses a very sparsely populated country, however, it is a link in one of the main routes from Tampa, around the Gulf Coast to Pensacola. The people of this section needed a road of some kind very badly as the deep sand was practically impassable.

On account of no Railroad facilities or material in this section, a higher type of pavement was practically prohibitive. Necessity being the Mother of Invention started the investigation and experiment with "Mixed-in-place Sand Asphalt," which has now passed its experimental stage, and to date fifty-one (51) miles of asphaltic pavement have been constructed and many more miles of similar construction is anticipated for the future.

16

Chicago Manual of Style

Florida. State Road Department. State Road Department Bulletin: Mixed-in-Place Sand Asphalt in Florida, 1932. 1932-01-01. State Archives of Florida, Florida Memory. <https://www.floridamemory.com/items/show/318830>, accessed 18 February 2026.

MLA

Florida. State Road Department. State Road Department Bulletin: Mixed-in-Place Sand Asphalt in Florida, 1932. 1932-01-01. State Archives of Florida, Florida Memory. Accessed 18 Feb. 2026.<https://www.floridamemory.com/items/show/318830>

AP Style Photo Citation

(State Archives of Florida/Florida. State Road Department.)

Listen: The Blues Program

Listen: The Blues Program